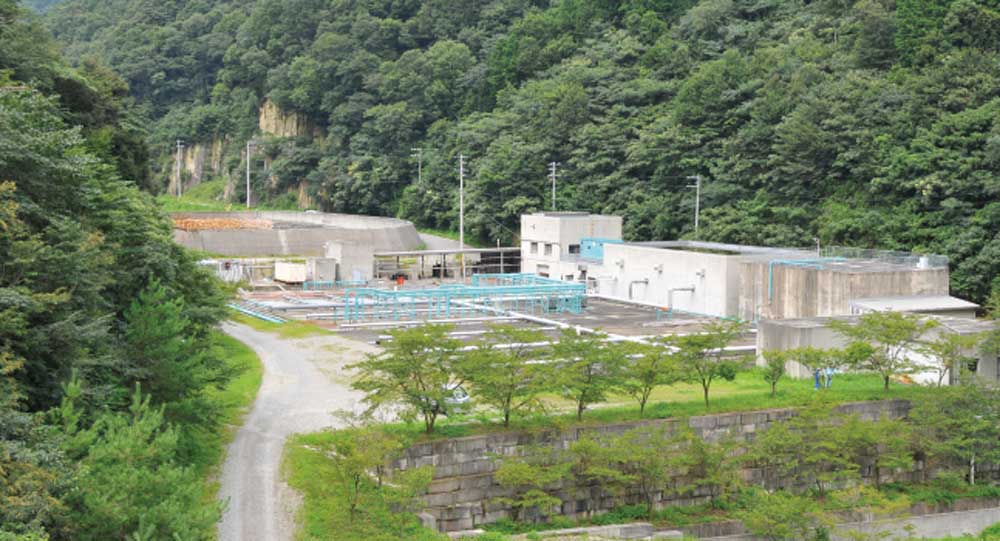

About the Leachate Treatment Facility

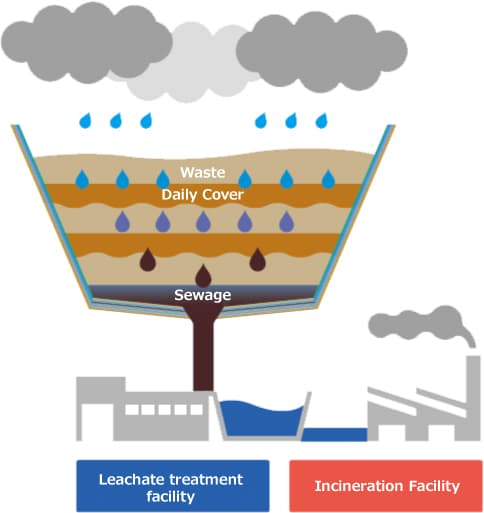

Drainage water from the land disposal site is collected in our water purification facility and thoroughly purified by membrane treatment.

At our leachate treatment facility, we use recycling of anaerobic and aerobic microorganisms to achieve efficient denitrification; and we have had very good results with cultures of bacillus soil bacteria for deodorizing and improving the quality of water. Also, using submerged membranes at the final treatment stage has enabled us to produce stable treated water with almost no risk of bulking (failure of sludge to settle out) despite load fluctuations.

At our leachate treatment facility, we use recycling of anaerobic and aerobic microorganisms to achieve efficient denitrification; and we have had very good results with cultures of bacillus soil bacteria for deodorizing and improving the quality of water. Also, using submerged membranes at the final treatment stage has enabled us to produce stable treated water with almost no risk of bulking (failure of sludge to settle out) despite load fluctuations.

Overview

Leachate treatment facility(constructed in May 2002)

| Form/Type etc. | Nitrified liquid circulation membrane separation activated sludge method |

|---|---|

| Capacity | 2,000 ㎡/day |

| Main Facilities | Pretreatment + calcium removal + biological treatment + membrane treatment + activated charcoal + sterilization |

The treated water is reused partly as coolant for the incineration facility at our Tōon City location (Frep Tōon), allowing us to do our share of thermal recycling.

The treated water is reused partly as coolant for the incineration facility at our Tōon City location (Frep Tōon), allowing us to do our share of thermal recycling.

Submerged Membrane Treatment System

This is a fluid-immersed membrane separation system using microporous membrane film developed for the purpose of environmentally friendly water treatment.

N.B.: The system uses microfiltration (MF) membranes with 0.4 μm nominal pore diameter through which even E. coli bacteria are unable to pass.

|

The membrane is submerged in an aeration tank. This facility houses 4 water tank series containing eight units; each unit contains 200 membrane sheets, making a total of 6,400 membranes. |

|

Submerged Membrane Cartridge The membrane film bonded to both faces of the cartridge is made from microporous chlorinated polyethylene. The treated water passes through the spacer and is discharged via the nozzles. |