SST Plant

Incineration and calcination + carbonization plant

Incineration 120 mt/day, calcination 360 mt/day, carbonization 24 mt/day

In simultaneous operation, this facility is capable of calcining 360 mt of contaminated soil and incinerating 120 mt of waste per day.

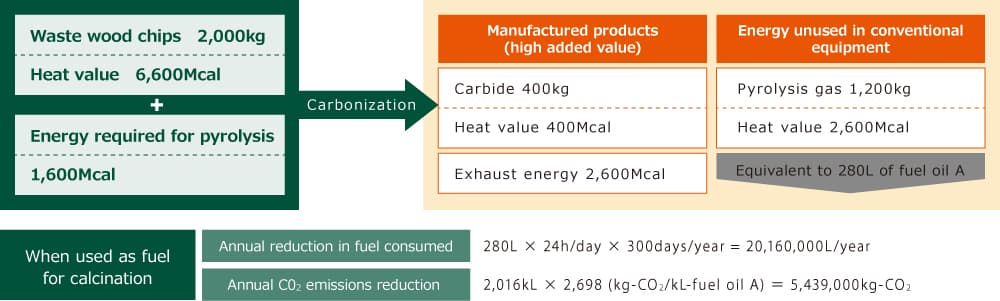

The facility includes a carbonization furnace capable of processing 24 mt of wood chips per day, and its design allows pyrolysis gas from the furnace to be used as a heat source for calcination, saving energy. The energy required for the wood chip carbonization comes from residual heat produced by the incineration and calcination facilities.

Using Pyrolysis Gas to Reduce CO2 EmissionsCalcination equipment requires large quantities of oil or other fuels. Although carbonization using conventional equipment generates pyrolysis gas as a by-product, up to now energy has not been efficiently recovered from this process. Our facility combines calcination and carbonization, allowing pyrolysis gas from carbonization to serve as fuel for calcination and achieving maximum energy recovery efficiency. Energy recovered from waste wood can be considered carbon neutral, and it contributes to lower CO2 emissions. Also, the fact that the energy needed for carbonization comes from waste heat means that this process uses zero fuel. Carbonization products find use as soil improvement additives and other high added value products. In addition, the warm air generated by an air heat exchanger is used effectively – for example to prevent white smoke formation – making this a highly energy-efficient system.

SSH plant

Incineration and calcination + electricity generation plant

Incineration 120 mt/day, calcination 360 mt/day, electricity generated 800 kW

Facility capable of incinerating 120 mt, chiefly industrial waste and general waste, per day

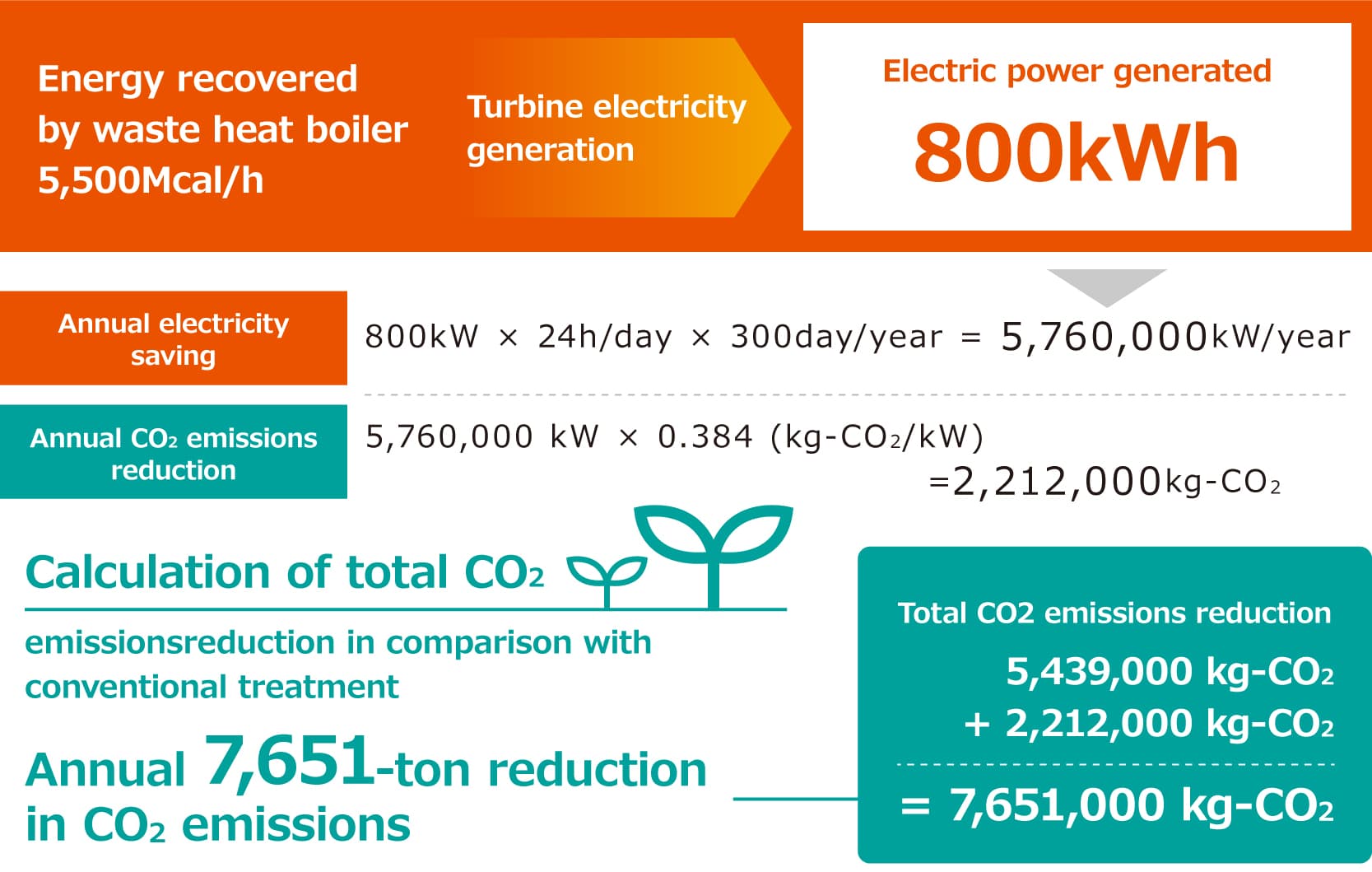

Driven by heat recovered by the boiler, the steam turbine generator produces 800 kW of electricity.

Electricity Generation and CO2 Emissions Reduction from Waste Heat UseHeat energy generated during incineration and calcination is converted to electric power by a waste heat recovery boiler and steam turbine. All the electricity produced is used to supply power on our site, helping to reduce our plant’s energy consumption.

Appropriate Waste for SSH and SST Plants

| General waste | Garbage, bulky waste, cinders, sludge, excretions, waste oil, acidic waste, alkaline waste, animal cadavers and other filth or unneeded items |

|---|---|

| Industrial wastes | Waste plastic, sludge, waste wood, paper scraps, waste fibers, infectious waste, waste oil, plant and animal residue, acidic waste, alkaline waste, inedible animal parts, scrap metal, waste glass, waste concrete and ceramics, cinders, dust and soot, slags |